Material

|

Color

|

Temperature range

|

Specific characteristics

|

| EPDM | Black | -25°C/+110°C | Standard rubber for a gastight and watertight sealing (for example heating pipes and water pipes) |

| Fire Safe | Red | -30°C/+120°C | Fire retardant rubber (also gas and watertight) |

| Nitrile | Blue | -25°C/+110°C | Resistant to the influence of oil and greases (for example hydraulic installations) |

| Silicone | Brown | -60°C/+200°C | Resistant to great differences in temperature (for example in cooling and steam pipes) |

| Viton | Green | –25°C/+200°C | Resistant to the influence of chemicals (for example in laboratories) |

Sizes and measurements

ASTM

DIN

DH-AP

PVC

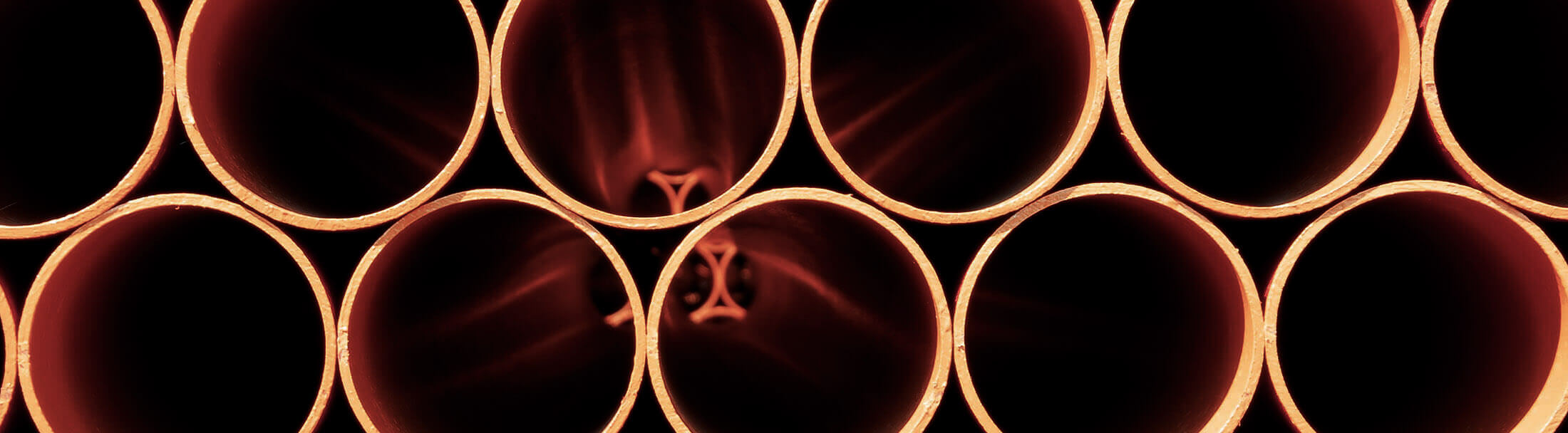

The PSI sealing system is the ideal sealing system for a singular transit of pipes or tubes. The plug consists of two equal, half round rubber parts, and can be used for four applications:

- Steel casing tubes (ASTM)

- Steel casing tubes (DIN)

- Standard bore holes and aluminium pipes (DH-AP)

- PVC pipes

Dependent on the chosen rubber quality of the PSI plug, a gastight, watertight and/or fire resistant sealing is created.

Certification & Warranty

The lifespan of the products is guaranteed for 25 years. This warranty can only be given, when the right plug is chosen, the plug is used in the right way, and stored in a cold and dark place. Furthermore, this is no warranty on the right method to mount, the dynamic load, the influence of corrosive materials and/or chemicals, etc.

For additional information please contact our PSI consultant: